CERTINA PACKAGING GROUP

The companies in the CERTINA PACKAGING GROUP are highly specialized experts for innovative and sustainable plastic packaging, and can look back on a total of 300 years of plastic processing experience.

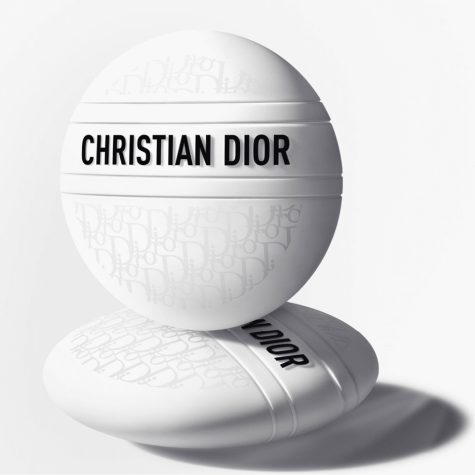

Thanks to our different manufacturing technologies, which range from injection moulding to plastic blowing processes and co-extrusion, we offer our customers the major advantage of implementing the best possible packaging solution for their product lines across companies. The cosmetics industry is particularly reliant on our expertise for producing top quality brand packaging.

Our comprehensive standard portfolio ranges from bottles and flacons with a wide variety of closing and dispensing options to jars and cans and also sticks and roll-ons. However, we also develop tailored solutions for customer-specific packaging requirements. Our wide range of in-house refining techniques such as screen printing, lacquering, hot foil stamping and metallization are an invaluable advantage, which give the brand packaging the company's individual look and make it unmistakable.

The CERTINA PACKAGING GROUP consists of the following companies:

HK COSMETIC PACKAGING GmbH (Germany)

QUALIFORM COSMETIC PACKAGING (France)

BEAUTY PACKED

IN PERFECT BRAND QUALITY

HK COSMETIC PACKAGING, which is based in Creidlitz near Coburg, specialises in the production of innovative, exquisite plastic packaging for international customers, predominantly from the cosmetics industry. With more than 100 years of experience and state-of-the-art production, we are the absolute specialists for injection moulding and compression moulding.

We can provide you with a top quality standard range of thin-walled and double-walled cans, brilliant thick-walled jars, exceptional sticks and roll-ons and also suitable closure options. We can give your brand packaging a completely unique character with our first-class refining techniques, which range from screen printing to hot foil stamping and metallization. Of course, we can also create unusual custom-made products in our in-house tool shop to make your primary packaging completely individual. You can also rely on our expert knowledge in the area of sustainable packaging solutions, where we can provide products made from recyclable monomaterials (PP, PET, HDPE), recycled polymers (rPP, rPET) and also biodegradable products such as wood-based solutions.

At HK COSMETIC PACKAGING you will get a complete package for your brand packaging – from consulting, design, development and material selection to tool manufacturing, project and quality management and also production, finishing and supply chain management, whereby everything can be provided from a single source – competent and made in Germany.

Location: Coburg-Creidlitz, Germany

Products: Jars, sticks, roll-ons, closures, accessories

Industries: Cosmetics, parapharmaceuticals

Technologies: IM (injection moulding), IBM (injection blow, mouldign), CM (compression Moulding / Duroplast)

Dekoration: Screen printing, lacquering, hot foil stamping, metallization

LUXURY AND QUALITY

IN THE MOST ELEGANT FORM

Qualiform is a manufacturer of plastic cosmetic bottles based in France. We produce packaging for dozens of international companies such as Chanel, Estée Lauder and LVMH. We can supply elegant standard bottles which you can easily customize (material, colour, decoration...), and also customized packaging solutions (your own form, shape, design...). We ensure that we use the most suitable and innovative materials for your cosmetic packaging.

Brands can choose from our comprehensive range of decorating techniques to make their packaging truly unique, including screen printing and hot stamping.

Location: Oyonnax, Frankreich

Products: Bottles

Industries: Cosmetics

Technologies: EBM (Extrusion blow moulding), Co-Ex (Co-extrusion), ISBM (Injection stretch blow moulding)

Decoration: Screen printing, hot stamping

1001 POSSIBILITIES

EXPERT IN VARIATION AND INDIVIDUALITY

REBHAN is a traditional German company with 70 years of packaging expertise in the manufacture of unusual bottles and flacons using extrusion and co-extrusion processes. We develop and produce a constantly expanding range of high-quality standard packaging which can be decorated in-house in an almost unlimited number of ways. We can also offer you individual, tailor-made solutions which are truly unique.

Our core competencies include the production of thick-walled glass-like flacons which do not need to fear comparison with glass thanks to their absolute brilliance, precise corners and edges and their high-precision stamping. We are experts in the production of Heavy Wall PET bottles, whose thick walls and stability are becoming increasingly popular in the cosmetics industry. Of course, we also have comprehensive knowledge of mechanically or molecularly recycled polymers and bio-based materials.

REBHAN impresses both internationally renowned brand manufacturers from the cosmetics, parapharmaceuticals, washing and cleaning industries with its experience, innovative spirit, top quality and expertise, and also creative start-ups, who we support right from the outset and are not afraid of taking unconventional directions with regard to materials and designs.

Location: Stockheim, Germany / Poznan, Poland

Products: Flacons, bottles, closures, accessories

Industries: Cosmetics, pharmaceuticals, washing/cleaning products, chemical products

Technologies: EBM (Extrusion blow moulding), Co-Ex (Co-extrusion),

ISBM (Injection stretch blow moulding), IBM (Injection blow moulding)

Decoration: Screen printing, lacquering, hot stamping, embossing, metallization

EVERYDAY HEROES

SAFELY PACKED

TRASSL POLYMER SOLUTIONS was established in 1957 as a family-run business in the Bavarian municipality of Immenreuth, since when it has specialized in the manufacture of plastic containers. The company concentrates on the automotive, food and chemical industries, and uses extrusion blow moulding systems to manufacture both standardised and customised bottles as well as a wide range of canisters and tubular bodies made from PE, PP, PET and PVC, with capacities ranging from 10 millilitres to 30 litres.

As well as providing individual customer support, we have our own tool shop, a screen printing department and an automated labelling system. Furthermore wie have our own testing equipment and a test facility. Among other things, our product range includes spray caps, wide-neck jars, canisters, round bottles and oval bottles. TRASSL POLYMER SOLUTIONS also manufactures flat bottles, flip top caps and rectangular bottles.

Location: Immenreuth, Germany

Products: Customisations, tubular bodies ranging from 10 ml to approx. 30 litres

Industries: Automotive, chemical industry, washing/cleaning product industry

Technology: EBM (Extrusion blow moulding)

Decoration: Screen printing, labeling